MM AQUA TECHNOLOGIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MM AQUA TECHNOLOGIES LTD.

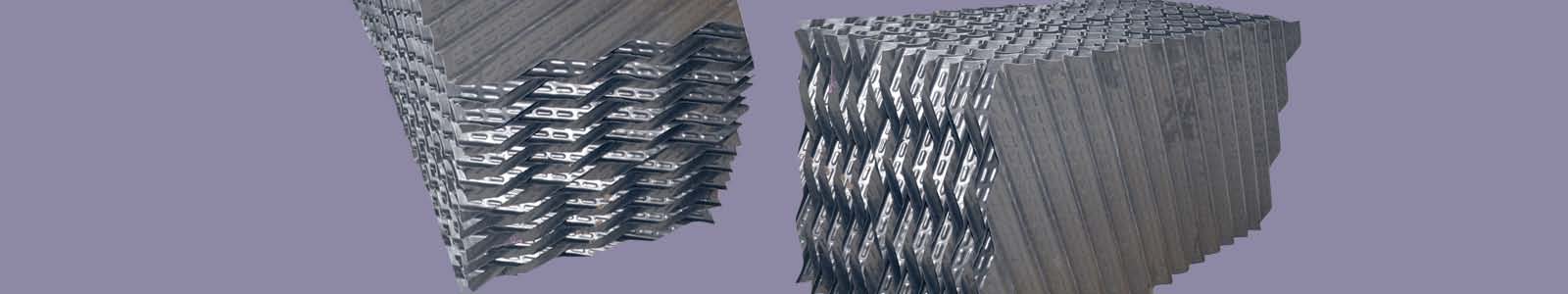

Film Fill

MM Aqua is into manufacture and marketing of various types of fill design suitable for different water quality. These fill Media are manufactured meeting CTI standards.

Fill Media manufacturted is of international quality and are prefered by leading consultants like NTPC, Fitchner, M N Dastur, Desein, TCE, EIL and NPC etc and is used by all leading Cooling Towers manufacturers.

Fill media manufacture by MM Aqua is exported to countries like Malaysia, Singapore, Thailand, Middle East, Canada, Australia, South Africa, Brazil, UK etc.

MM Aqua has big production capacity to meet large order Qty in required project schedule.

MM Aqua offers following type of fill media.

Film Fill : – C10.12 / C10.19 / C10.27

Advantage of MM Aqua film fill.

Continuous Forming : Continuous forming process allows free flow of material during the stage of formation. Additional requirement of raw material is met hence no thinning takes place at crests & troughs.

Double Edge Folding : MM Aqua’s manufacturing technique has the ability to fold the edges of the sheets providing stronger edges, which gives extra protection against water loads and shear force form beams. It also protects the fill from damages during installation & maintenance.

Uniform Thickness : Provides uniform strength in fill sheets all along the fill surface.

Micro structure : Unique shape and dimension provides long retention time and thus longer time for heat transfer.

Longer Length : Allows the structural designer to reduce number of support beam thus inturn reduces the pressure drop and cost of construction.

In Conventional vacuum forming the sheets being formed needs anchoring both ends of the sheet, which results in stretching of material. Weak spots of lower tickness at crest and trough and at times also on flute surface are formed. Vacuum-formed sheets suffer from unpredictable thikness due to material stretching during the process. reduction in thickness is to the tune of 40%. However, by leaving one end free during continuous roll forming, MM Aqua avoids the undesirable results.

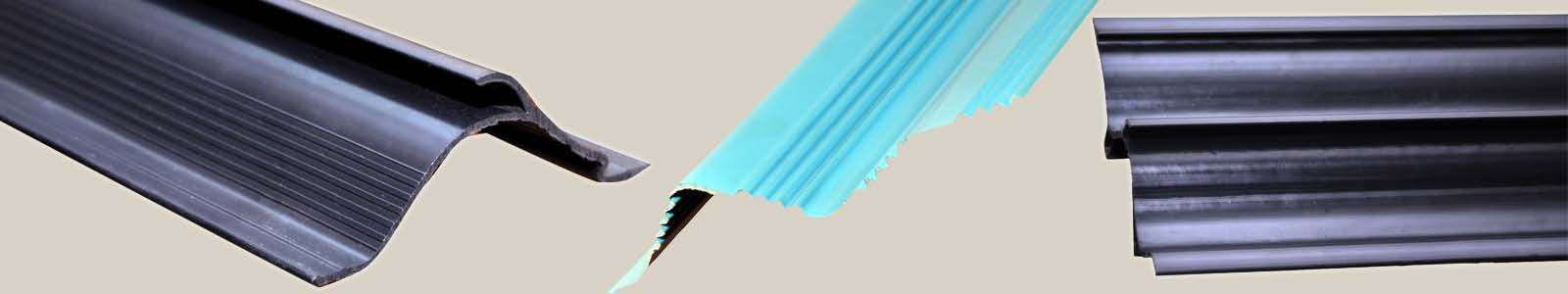

Splash Fill

V bar type Splash bars are manufactured out of a very modern extrusion line to ensure properly formed strengthening rib and perfect fitting V-bar support to bench tie.

V bar Splash fill is manufactured in option of rhombus and round punches.

Turbosplash

Turbosplash fill is very suitable fill for brackish water quality and ambinent prone to algae growth and thus leading to clogging of fill. Turbosplash fill has baffel approx 50mm wide apart and thus do not clog. Spalsh actions makes the fill self cleaning adn thus provide longer life.

Mist Eliminator

Mist eliminator produced by MM Aqua are U V stabilised made out of virgin PVC in 3 different designs to meet following engineering application.

Textile units .

Air washers / Air handling units.

Paint Booth.

Gas Turbine Air Intake Systems.

Mist eliminator is an implement separator designed for horizontal gas flow. It is

composed of sine curve shaped flow contours assembled with phase separating chambers .

Our three types of mist eliminators are :-

T-100

T-200

T-400

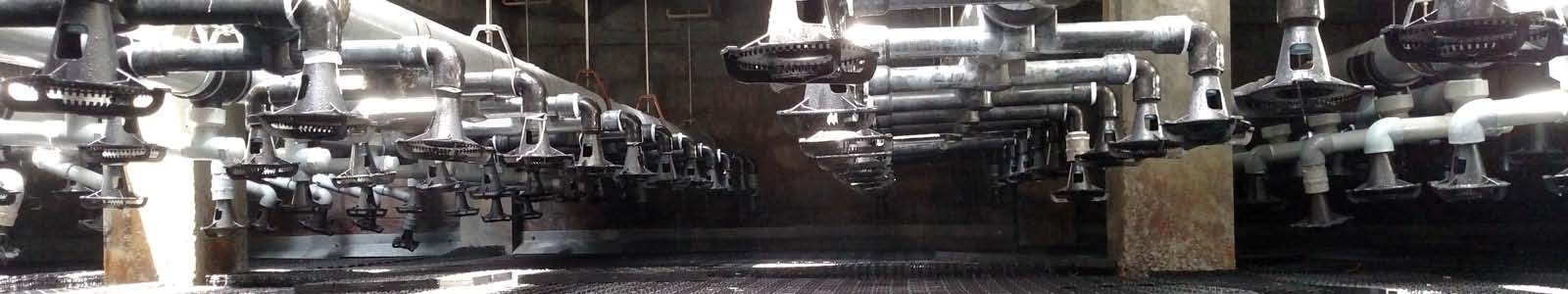

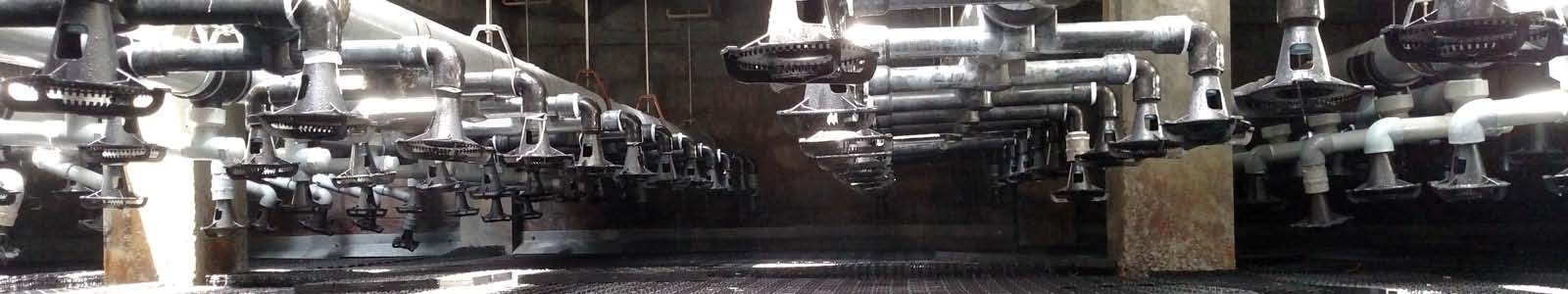

Distribution Nozzle

The MM Aqua solid rectangle spray nozzle consists of a standard plastic body and a choice of four different plastic tabulators and orifice inserts. The result is four different water capacities. In order of increasing capacity, the nozzles are 1-A, 1-B, 1-C and 1-D.

The standard plastic used for manufacturing the nozzle body is suitable for service at temperatures up to 180 F. Each nozzle is supplied with silicone gasket, plastic tabulator and orifice, forming the ‘ nozzle assemble’ .

Salient features :-

Made of corrosion resistant plastic.

Uniform rectangular distribution.

Overlapping area is least and portion remains dry as in circular distribution.

Water capacity can be readily changed within single nozzle body.as we use same body for different water flow capacity.

Easy twist lock installation and removal needs no tools.

Loss weight and cost in piping systems.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.